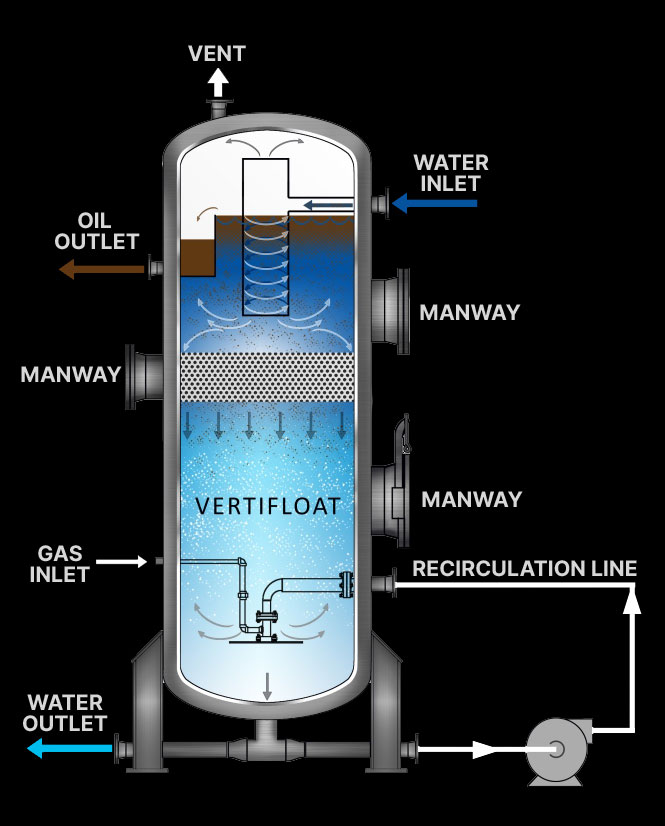

VertiFloat CFU

Compact and reliable, our VertiFloat purifies wastewater using 2-stages of oil droplet coalescence along with a single flotation-compartment conserving precious deck space and weight.

VERTIFLOAT™ COMPACT FLOTATION UNIT

FLOTATION DEVICES ARE USED AS A FINAL POLISHING STAGE

Flotation devices are designed to remove (or polish) the most difficult contaminants from the produced water – small droplets of oil and small, oil-coated solids. Therefore, flotation equipment is subject to the following general limitations:

Percent removal of contaminants:

Single-cell IGF: 50-90%

Inlet contaminant concentration:

Single-cell IGF: 200 mg/l, max (<100 mg/l preferred)

KEY FEATURES OF VERTIFLOAT™ DESIGN

- Compact, efficient, reliable

- Designed primarily for floating platforms or fixed platforms with limited deck space Lowest downward fluid velocity )

- Process 30% over design flow rate

- Produced Water Inlet releases gas slugs avoiding upsets in the oil pad

- Distributes water evenly over the vessel's cross section Triple stage oil droplet coalescence

- Precoalesces oil in water inlet through centrifugal force

- ESI Matrix™ coalescing media installed for second stage separation

- Specially designed effluent nozzle prevents fluid short-circuiting

- Standard chemical injection system efficiently disperses high MW flotation polymers

gallery